AC660 System (Formerly AC24M)

While Aerocom offers ongoing maintenance to owners of the AC24M system, the AC660 is the new standard solution for retailers and other organizations interested in installing a new system. If your organization currently uses an AC24M system and is in need of support, please get in touch with our 24/7 support team by submitting a service request form on our website, or by calling 800-741-5096, and we will be happy to service your equipment.

A versatile tube system for improving efficiency in any environment

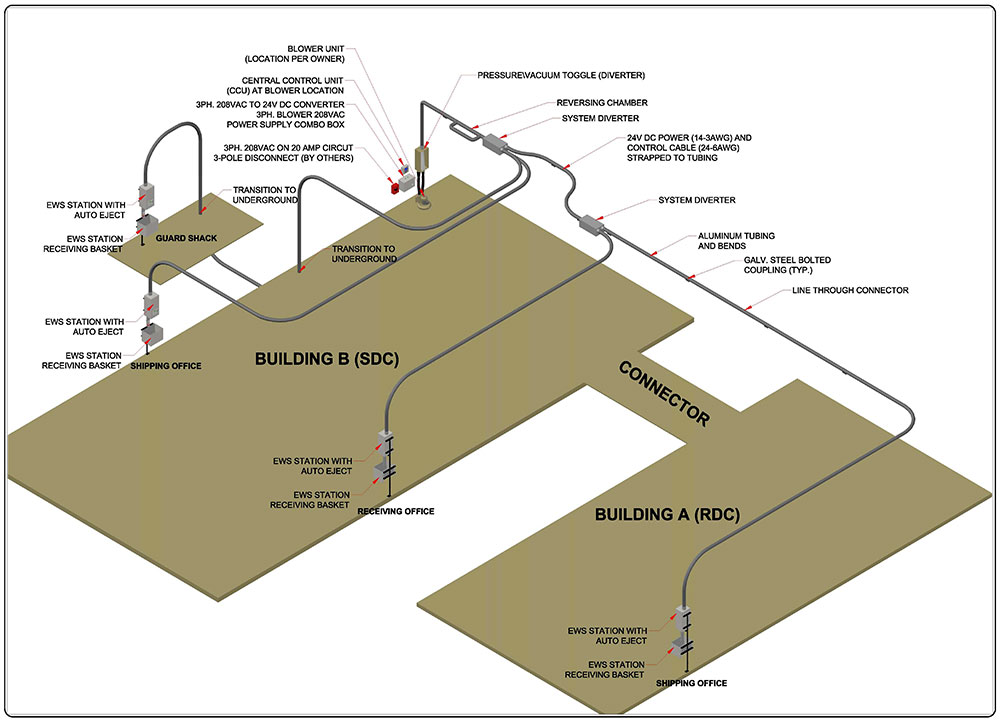

The AC660 is a tried-and-true system that connects up to 99 points of transfer. This versatile system can be installed inside or outside, or in cold- or hot-sampling facilities, a great choice for organizations that transfer time-sensitive materials. The AC660 is commonly used in the following industries:

The AC660 is a tried-and-true system that connects up to 99 points of transfer. This versatile system can be installed inside or outside, or in cold- or hot-sampling facilities, a great choice for organizations that transfer time-sensitive materials. The AC660 is commonly used in the following industries:

Features

One of the most attractive features of the AC660 is its unique queuing ability, in which the system can dispatch multiple carriers according to priority. Multiple operators can insert a carrier into the station and enter the command to send it to the desired location. The system will record the transaction ID in the order of the commands entered and the station will dispatch the carrier according to this priority. A full audit trail including personalized transaction information will automatically be logged. Reports can be printed for comparing records if ever necessary. Other features include:

- Fully automatic, variable, microprocessor-controlled system that does not require a dedicated PC

- Bidirectional system with programming options for master/substation transfers

- Configures up to 99 outlying station locations to process transfers with one central control unit, or CCU, and blower.

- Stores the last 5000 operations in system log

- Audit-trail tracking and report creation

Benefits

- Enhanced security. Offers several levels of identification security for tracking transactions with cash or valuables.

- Compatibility. System configuration is compatible with almost any need.

- Remote maintenance. Comprehensive System Diagnostics from the CCU allows technicians to perform remote testing, monitoring, and troubleshooting of system.

- Built-in safety protocols. In the event of power failure, system automatically returns carriers to the master station to prevent possible carrier collisions.

Why Choose Aerocom USA?

|

Durable Products We develop high-quality systems and products with the widest range of user features and reliability. |

Custom Solutions We work with trained architects to design, manufacture, and install custom systems that are the perfect fit for your organization. |

24/7 Support Line We’re dedicated to keeping your system in perfect working order. Our team is available around the clock to fulfill maintenance requests and answer questions. |

Experience You Can Trust When you work with us, you’re getting access to a global team of experts and 80+ years of experience in pneumatic tube systems. |

Build A Custom Pneumatic Tube System with Aerocom USA

Backed by more than 80 years of experience, Aerocom specializes in developing custom pnuematic tube solutions for a variety of organizations. From design to installation to maintenance, our team is committed to helping you cut cost and improve efficiency. To learn more about our services, speak with a member of our team by sending us a message or calling us at 800-231-4156.